Shaping Biofoam

Fall 2023, Course: Sustainable Materials Research Lab

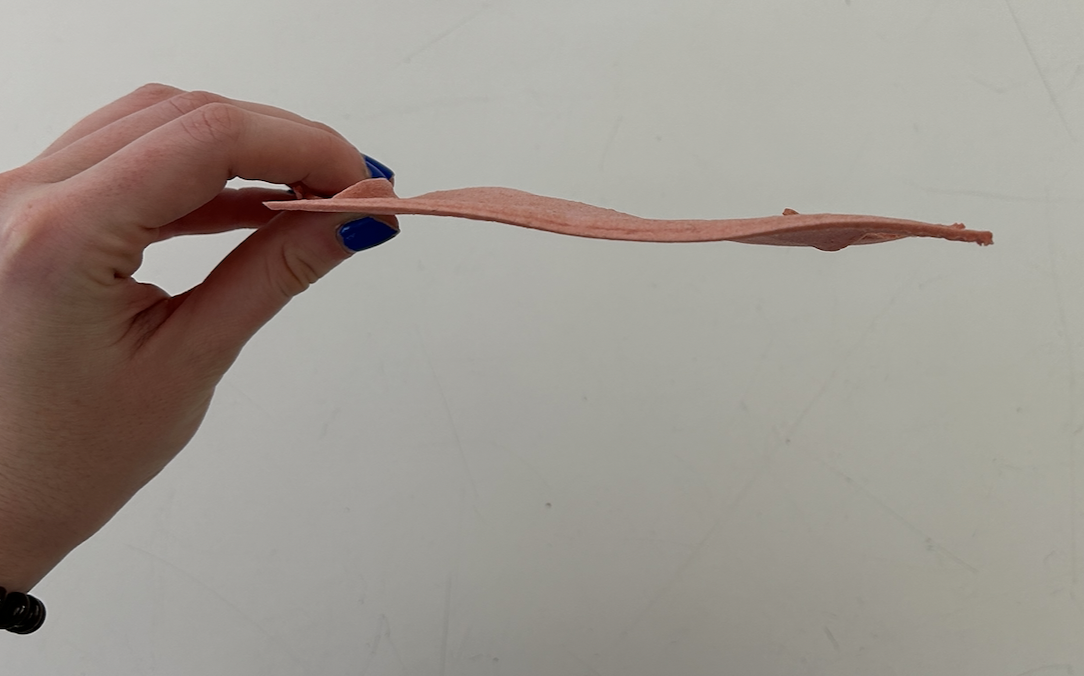

A mixture of agar agar powder, dish soap, and water dries into a light, relatively solid material. As it dries though, it warps unpredictably. I experimented with ways to flatten and mold it.

Research question: How can we mold and shape biofoam to create light, sturdy objects and enclosures?

I went through many iterations and batches, details of which can be found here. Below is a summarized version of my research and findings.

PART 1: Make the material

I used the Cloudy Day recipe by Yeseul Song and Priyanka Makin

Ingredients: 800mL of water, 45g of dish soap, 30g of agar agar

Equipment: hot plate, non-stick pan, spatula and spoons, digital scale, measuring cups, immersion blender, cooking thermometer, baking mold or tray

- Add ingredients to a sauce pan and mix

-

Turn on heat to low setting (140°F), stirring continuously for 5 minutes

-

Increase heat to 175°F, stirring continuously for 5 minutes

-

Increase heat to 212°F and use immersion blender to whip mixture for 5 minutes

-

Remove the immersion blender and lower heat to 175°F, stirring continuously for 7 minutes

- Remove from heat and pour evenly onto 2 baking sheets.

Note: The material takes about five days to dry completely.

PART 2: Restrict warping during drying process

The material begins to set just a minute after it’s taken off the heat. I cut out a piece and put it onto a plastic mesh sheet that came with the dehydrator I used.

I placed another mesh sheet on top so the material was sandwiched between the two, and weaved wire around the border to secure the two sheets together.

I put it in the dehydrator at 90°F for about ten hours and this was the result:

I presented this research at the 2023 ITP Winter Show